Production Process

Our purpose built manufacturing facilities provide us with the ability to produce our in house designed and developed products, materials and processes.We produce composite products, especially with carbon fiber and fiber glass, from our local based facilities all built to meet or exceed the exact requirements of our customers.Our manufacturing facilities and multi skilled processes and flexible workforce enable us to meet all our customers' needs with quality products delivered on time.

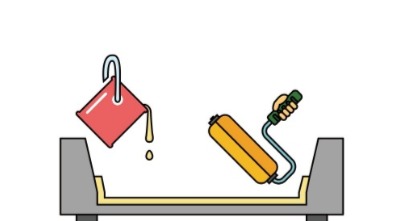

Hand Lay-up

of diversity production and the large item production.

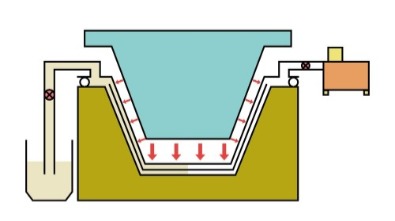

Vacuum Molding

This process is a vacuum-assisted, resin transfer process with a flexible solid counter tool for the one-side surface compression. It is one of major interest for various molding applications as it promises performance improvements and cost savings over traditional methods.

Advantage: Excellent weather resistance, good adhesion and consistent product thickness and weight.

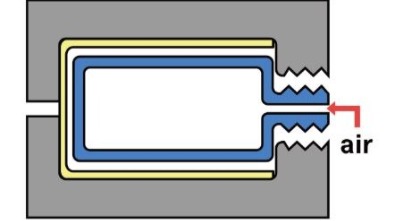

Blow Molding

It basically consists of taking fiber and resin substrate; used to inflate soft plastic into a mold cavity. Over a long-term period of research, this process has become one of our unique technical characteristics.

Advantage: Excellent weather resistance, lightweight products which is both strong and rigidity, this method is suited for complex main body, pipe and complex tube

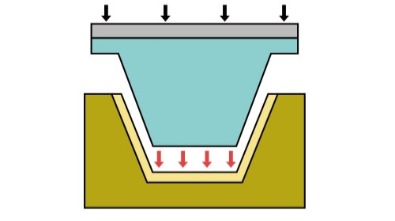

Prepreg Carbon Fiber

Dry carbon fiber is that use prepreg carbon fiber / carbon fiber sheet heating to a pliable and to pressurize it forming it on the mold.

Advantage: Can be mass produce, excellent product size consistency, not easy to deform and is weather resistence, strong and rigid.

Company Spirit

Customization

We could evaluate any customized project,

just send us your drawing!

On-Time Delivery

When we confirm the ship date with our customer, we always ship on time.

After-sales Service

In order to do the continuous improvement,

we pay attention on every customer's feedback.

Rich OEM experience

Based on more than twenty years OEM experience, we can handle any kinds of situation and make the perfect customer satisfaction.

OEM / ODM

Sorts of glass fiber and carbon fiber process and professional equipment can meet the suitable manufacture process of products. Our experienced technician can help you to develop a new mold and manage the products.

3D CAD Design

Able to develop customized mold and product with help of Computer Aid Graphic Design. A prototype made from 3D printing is more accurate and under control on correcting dimension and it works more efficiency.

Packing & Storage

Using lot number system to organize customer product for shipping management. We do quality control while the product manufacturing, and our package worker will inspect the product again before packing. We use the package of anti-collision materials or customized package to make sure your products being on time and securely.